Chiyogami and Yuzen Washi

Chiyogami is a type of paper decorated with traditional Japanese patterns printed in color. Due to the development of dyeing techniques during the Edo period (1603-1868), it became accessible to townspeople, becoming known as origami.

Every single sheet of chiyogami at REKAO is made from durable washi paper with vibrant colors achieved through hand-dyed yuzen techniques. Learn the key steps for crafting hand-dyed yuzen washi below.

Step 1

Dyeing the Base Color

Step 2

Coloring in the Design

Step 3

Layering the Colors

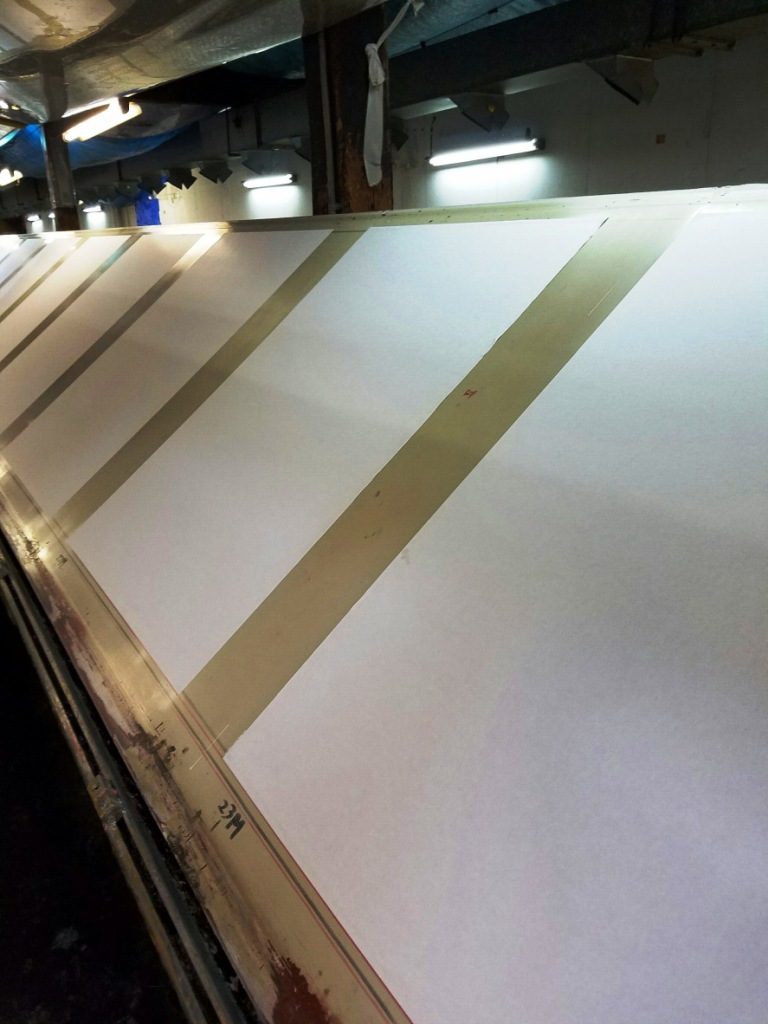

STEP 1

Dyeing the Base Color

First, we dye sheets of washi paper with a base color. The paper in these photos has been dyed with a special "chemical gold" variation, which brings out a more brilliant and vivid finish than regular gold dye.

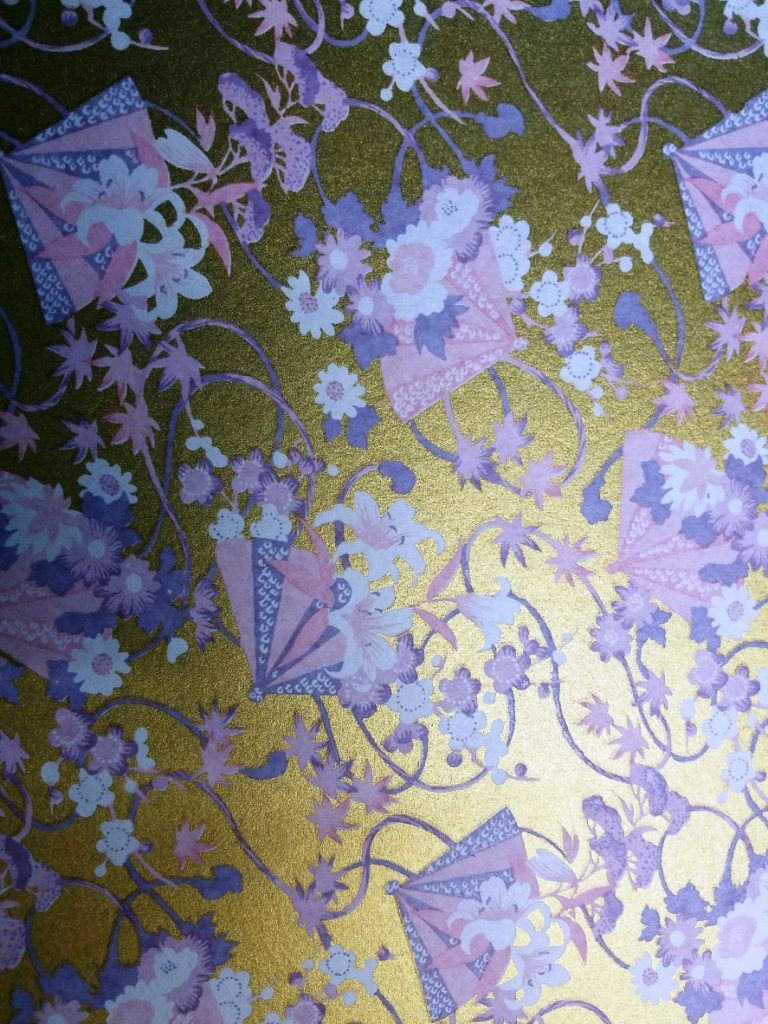

STEP 2

Coloring in the Design

Next, we begin to color in the design with stencils. As the cut-out design is printed with the help of silk mesh stretched across the stencil, this technique is also known as silkscreening.

STEP 3

Layering the Colors

We then repeat the step above for each color in the design. The photos below show how layer after layer of color is added, beginning from left to right. This takes a lot of effort due to the many stencils used for different colors, but it creates vibrant patterns that cannot be produced with regular printing.

STEP 4

Drying the Paper

Next, we dry the paper (around 25 sheets to a dyeing board) by warming it with heated wires on the back of the board and blowing it with warm air from above for about 10 minutes. With this, our hand-dyed yuzen washi is finally complete!

Traditional Yuzen Washi Patterns

Learn about typical patterns and designs used for yuzen washi.

Cherry blossomsSakura

・Beloved by Japanese people, cherry blossoms are considered as one of Japan's national flowers.

・Although it blooms in spring, it can be used for any season due to its status.

・They symbolize rich harvests and beginnings.

ChrysanthemumsKiku

・While they bloom in fall, they are used all year round as an auspicious symbol.

・Many variations exist, like kikusui, which combines chrysanthemums with flowing water, and kiku-karakusa, which uses intertwined vines.

PeoniesBotan

・Peonies begin as small, round blooms that go on to yield large, beautiful flowers.

・They symbolize happiness, wealth, and the aristocracy.

・Long ago, only those of high status were permitted to wear peony designs, leading to its current meaning.

Pine treesMatsu

・They are a symbol of long life, as the leaves stay green all year round.

BambooTake

・Quick to grow and full of vitality, they are said to have been used to wish for healthy growth for children.

・The famous shochikubai combination (pines, bamboo, and plum blossoms) was often used for Shinto rites.

PlumsUme

・They symbolize patience, prosperity, and elegance.

・It is said that people use them to express wishes for a safe birth, as ume sounds like the word for "be born."

PloversChidori

・They represent harmony and progress.

・Not only were these cute birds turned into a pattern, but they are also often used as designs for ordinary people.

Wave CrestsSeigaiha

・An auspicious design used as a wish for something to continue for all eternity.

・They represent a happiness that will never end, like the ever extending waves.

SnowflakesYukimon, Yukiwa

・They symbolize infinity due to having no starting and ending point.

・From long ago, they have represented connections and have been used as a lucky design.

TortoiseshellKikkomon

・A geometrical pattern consisting of joined hexagons.

・The name comes from its resemblance to the shell of a tortoise.

・It has been used as a lucky design that represents longevity.

・Different types include the komochi kikkomon (with two smaller hexagons inside the original hexagon) and the hanabishi kikkomon (with a flower crest inside).

CranesTsuru

・These mysterious birds represent longevity and the richness of life; it's said "cranes live for a thousand years, turtles for ten thousand."

・They also symbolize a good relationship between husband and wife.

・They have been used for kimono worn to celebrate happy occasions.

RabbitsUsagi

・They are bringers of good luck used to pray for the prosperity of one's descendants.

・Due to only going forward and their tendency to jump, they also represent rapid progress.